Digitalisation across Australian industries is a goal for many organisations moving forward, with the reality of new technologies such as artificial intelligence (AI), machine learning (ML), and software capabilities like digital twins already being used by many manufacturers, with interest rising.

Skills Lab’s Diploma of Applied Technologies (DAT) enables participants to develop the skills and knowledge required to undertake para-professional technical roles within Industry 4.0 manufacturing and/or engineering environments.

We had a chat with two current DAT participants – Mark Shepperd and Matthew Hardy to find out more about their journey so far…

What is your current role?

Mark: “I work with Lysaght, which is part of the BlueScope Group, and I’m a State Maintenance Manager based at Emu Planes.”

Matthew: “I’m a fourth-year electrical apprentice with HVTC and for the past three years I’ve been hosted by BlueScope Steel.”

Why were you interested in the Diploma of Applied Technologies?

Mark: “I’ve always been interested in improving maintenance systems – getting as much data from the machines into our CMMS (Computerised Maintenance Management System). I also have outside hobbies where I dabble in building my own drones and that type of thing, so I have a broader interest in electronics.”

Mathew: “My employer put an offer out in conjunction with BlueScope to all apprentices to apply if they are interested. From my personal preference, I like to further my education and get as much experience in different aspects as possible. So I thought I’d take every opportunity I get.”

How did you find the training?

Mark: “At first, I was sceptical of the self-learning approach. I wasn’t sure how going away into your groups and discussing the challenges, or working through it yourself was going to work. I thought it was pretty good in the end. If you did have any problems, you could always put your hand up and ask. The trainer sometimes challenges your ideas and makes you think again, which is a good thing.”

Matthew: “The teachers are very friendly and you’re able to contact them in and out of class. It’s very accessible. Even if you can’t attend every lesson, it can be negotiated to have extensions on due dates and whatnot. I think everyone should go for it if they have the opportunity. At the end of the day, you’re furthering your education – why not go for it!”

What technology did you use?

Mark: “One technology I enjoyed using was Autodesk’s Fusion 360 – a CAD (computer-aided design) drawing program commonly used across our industry. I knew a reasonable amount about it before the course, but I didn’t know quite a few of the shortcuts and that sort of thing. I was able to enhance my skills by putting my hands up and asking, “How do you do this” or “How do you do that” to improve my knowledge and be more efficient.”

Mathew: “You have a few choices when it comes to the technology you use, but I chose Fusion 360. We use a lot of Autodesk’s other software at BlueScope, so in that sense, the UI (user interface) and everything can be quite similar and it makes it a bit easier to pick up. Seeing the variety of people in the class, the software is a lot more accessible than typical software that is available to use. Once you get past that learning curve, it’s not too difficult for anyone to pick up.”

How has the training helped you in your current role or in your plans for the future?

Mark: “It’s definitely given me the confidence in using Fusion 360 and it’s given me access to Fusion 360 at work as well. All my latest drawings and designs have been on Fusion 360, so that’s one big change that I’ve made since doing the course. We also learned about ChatGPT, which I have used a little bit as a tool to support problem-solving. I’ve also developed internet search skills to help with day-to-day work.”

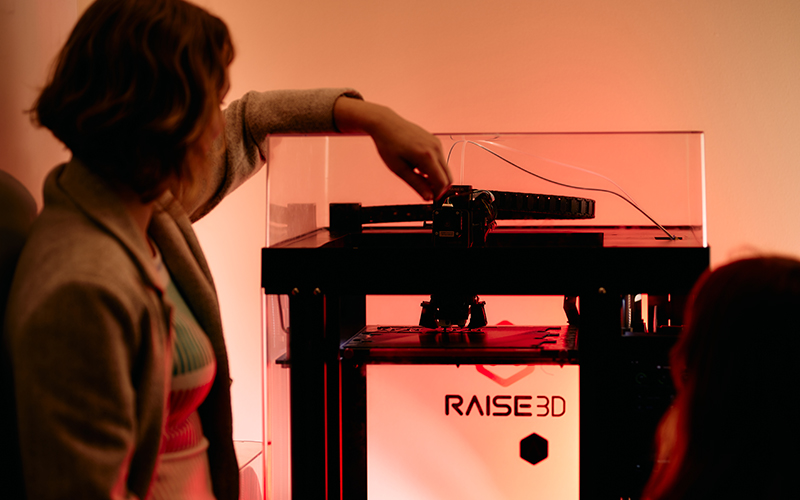

Matthew: “Learning about the different aspects of Industry 4.0 has been beneficial as some of these aspects such as 3D printing are already being used at BlueScope. A recent example of implementing skills learned in the diploma is a custom 3D-printed part I made to replace a broken component that is no longer manufactured. You are certainly more aware of what can be used to streamline maintenance and keep production up.”

What are your biggest takeaways from the course so far?

Mark: “The biggest benefit for me is being made aware of technologies like Digital Twin, which involves modelling a process in a digital world and using the Arduino kits that you can get to experiment with – which are fairly cheap and easy to use. It definitely gives you the confidence in experimenting, designing, innovating, being aware of the new technologies that are out there, and knowing where to go for information."

Matthew: “I wasn’t too aware of Industry 4.0 and it’s, of course, the way we are heading. So for the future, it’s good to learn and be on top of that stuff before it’s implemented. I’ve been doing a computer-aided design (CAD) and a computer-aided manufacturing (CAM) unit, which I have a bit of a background in. I do a bit of 3D printing and CAD at home and on the side. So, it was good to be able to access industry-standard software and be able to start implementing it.”

Is the Diploma of Applied Technologies for you?

Mark and Matthew are just starting their Diploma of Applied Technologies journey, with plenty more course components remaining to learn more highly relevant industry skills along the way.

The Diploma of Applied Technologies is anticipated to be delivered over a period of 18-24 months. This incorporates structured training delivery and opportunities for practice and reinforcement of skills including; self-directed study, research, project work and written assignments.

Where training is delivered under a contract of training, this will be 36 months in duration. Off-job training is expected to be either five days a week block delivery or 1 day a week on a part-time basis. This is open to negotiation with Industry employers.

If you have an interest in 3D CAD/CAM, are working in Industry 4.0 environments, PLC automation, SCADA, microcontrollers and digital troubleshooting, networking, commissioning, big data analytics, or digital twinning, or want to take your career to the next level – apply for the Diploma of Applied Technologies today.